Instruction of Facilities

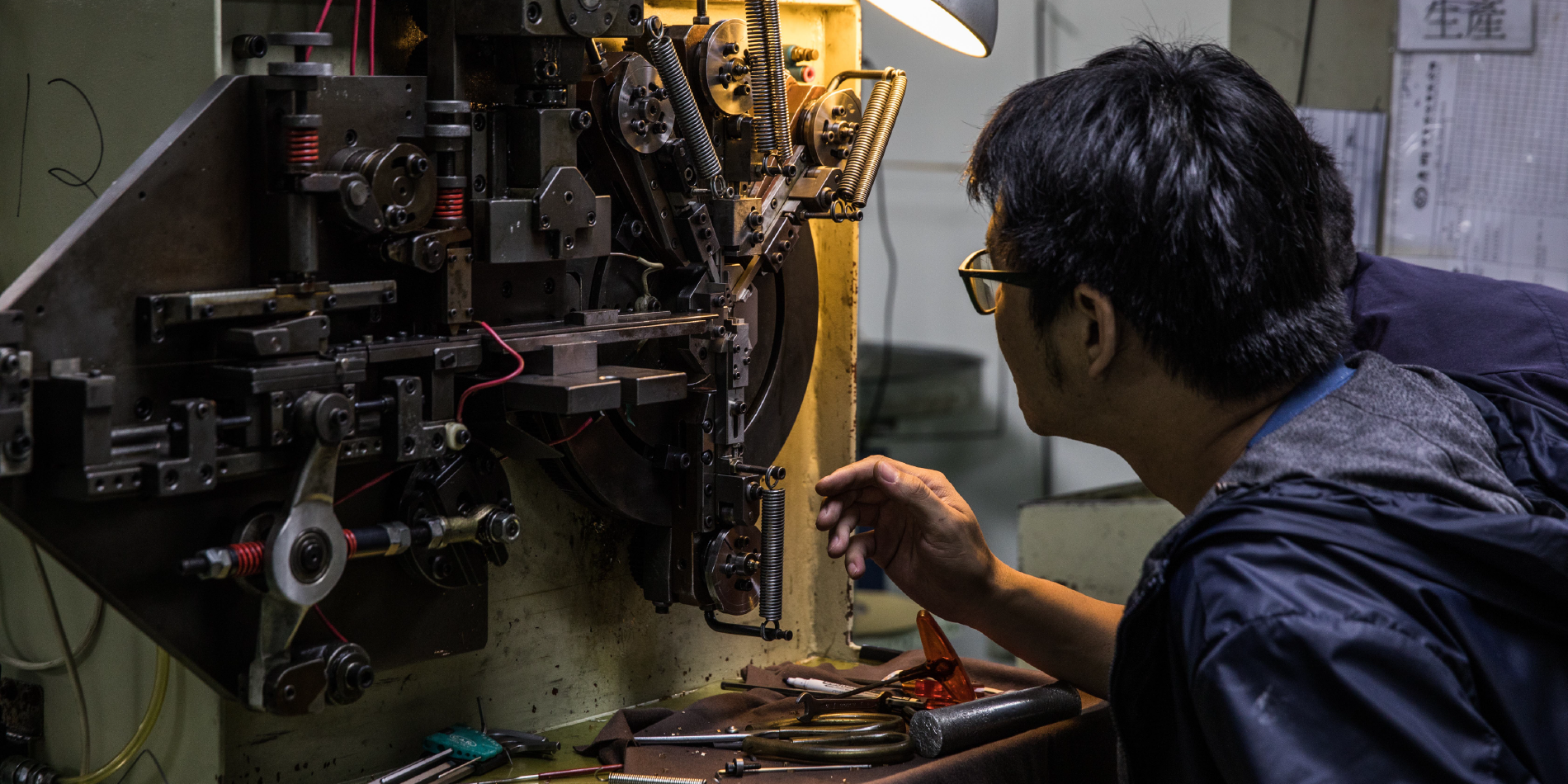

Tooling Design Division

In the process of tooling design and development, the important factor is to consider the material of use, ease of assembly, maintainability, reliability and fit of product characteristics.

We have absolute confidence of design and development to ensure tooling’s quality based on our professional tooling processing machine and professional personnel.

In addition, the tooling processing machine is necessary for tooling designers or maintenance.

It is just like a good partner. Once the tooling is damage, personnel can quickly and accurately repair and complete.

| Tooling Processing Machines | Spec. | QTY |

|---|---|---|

| Milling machine | 1.8# | 1 |

| Forming Grinding Machine | 3 | |

| Lathe | 2.0# | 1 |

| Saw machine | 1 | |

| Drilling machine | 1 | |

| Argon Welding Machine | 1 |

Production Division

We specialize in manufacturing of metal flat spring contact and hardware parts. The products we manufacture not only in Taiwan, but also have been used by customers all over the world. We trying to produce products with high quality insight.

This is a miniature metal part which is closely related to our daily life, which implies support for people's "living" and "convenience".

| Production Facilities | Spec. | QTY |

|---|---|---|

| Multi-axis Punching machine | 2T | 2 |

| Multi-axis Punching machine | 0.5T | 19 |

| Pneumatic automatic Punching machine | 250T | 2 |

| 160T | 1 | |

| 135T | 1 | |

| 110T | 6 | 80T | 2 | 60T | 3 | 35T | 2 | 25T | 2 | 20T | 2 |

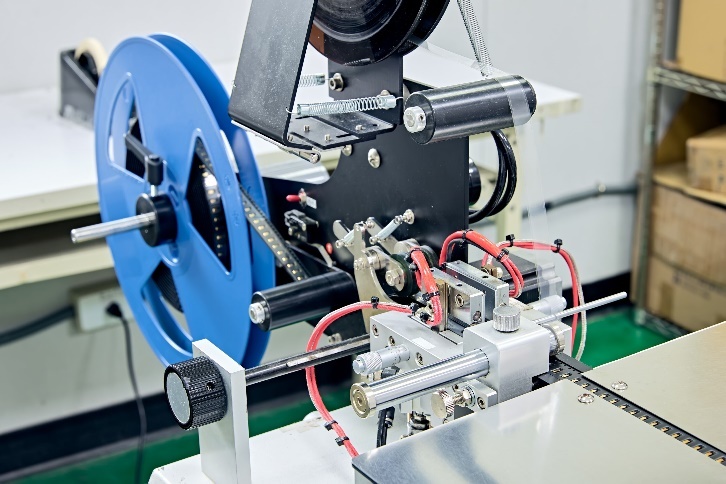

Packaging Division

After the completion of the product, the final procedure is packaging, from Embossed carrier tape design, forming, testing, packaging, Tailored for the product, and providing fastest and efficient carrier tape production and packaging.

Good packaging for the product, that is provide customers with the most assured quality of goods.

| Production Facilities | Spec. | QTY |

|---|---|---|

| SMD Taping machine | MT600(3L) | 4 |

| Carrier tape forming machine | 12-88 | 5 |

Quality Inspection Division

We carefully inspect designed metal spring contacts and various hardware parts, so that they can be utilized as key components and be more value-added. In the delivery, we use lightweight packaging to pay attention of quality first meticulously. All inspections are performed under professional tested equipment and procedures.

| Inspection Instruments | Spec. | QTY |

|---|---|---|

| 2.5D measurement instrument | 0-145mm | 2 |

| Tensile and pressure load test instrument | 0-3kg | 1 |

| Cursor caliper | 0-150mm | 4 |

| micrometer | 0-25mm | 2 |

| Height Guage | 0-600mm | 1 |

| Color-difference Meter(Coating) | 1 | |

| Brightness Meter(Coating) | 1 | |

| Film thickness Meter(Coating) | 1 |

Warehouse of environment

Our daily workplace is bright, clean and safety. This is our efforts to promote the projects and it can achieve more efficient works. Let keep every colleague have a comfortable workplace and safe environment of work. Definitely, we are continuing to move forward.